Transport

The tugger train control enables the delivery of loading equipment / empties to production lines at regular intervals and/or at one-off delivery times.

The stations and products can be created in the setup.

In the case of products, it is possible to specify a loading equipment, quantity and interval. For the stations, the product, the next delivery time and the status of the station can be set to active or inactive afterwards.

The cockpit provides a timed schedule of the train, as well as overall control of loading and delivery to a station.

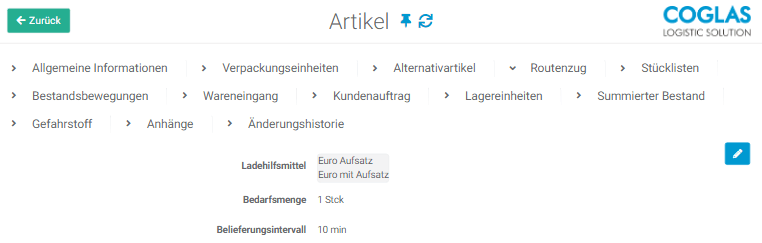

The Route form in the item master data offers the possibility to create a product for the specific article.

A product consists of a loading equipment, a quantity and the delivery interval.

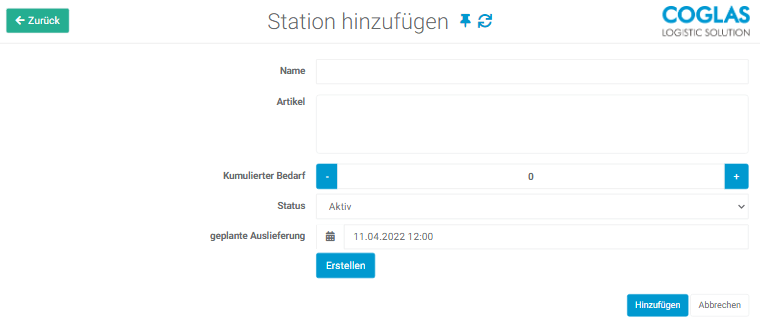

The Stations form shows the overview of already existing stations and offers the possibility to edit and add stations.

When creating the stations, the following parameters must be maintained:

- Name of the station

- Product to be delivered

- Selection from the types created in the master data (Master data » Articles » Route train)

- Cumulative demand (optional)

- Initial value of the initial delivery or corrected requirement quantity at any time after activation

- Station status

- active = When this value is set, a schedule entry with the current time plus delivery interval is created as an appointment in Planned status.

- As soon as a schedule entry changes from Planned status to Loaded or Delivered status, the system creates a new entry in Planned status.

- Idle = No new schedule entries are generated when the status changes.

- Planned delivery (optional)

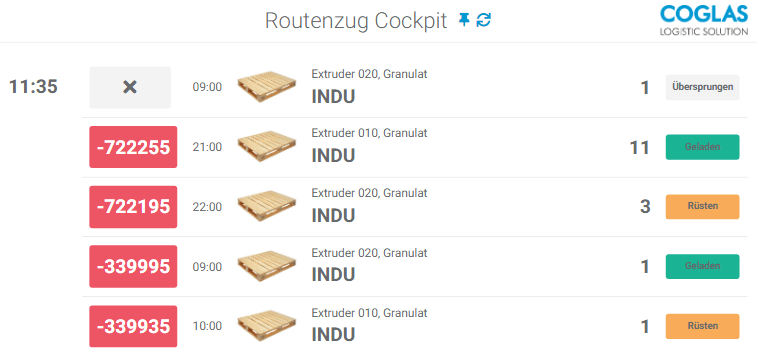

The cockpit shows the next delivery dates of the tugger train and offers the possibility of initiating different status messages. For each station, only the next delivery is displayed as long as it is unprocessed, i.e. not set up, skipped or delivered.

The deliveries configured in the stations are sorted in the schedule display of the cockpit in chronologically ascending order from top to bottom (next delivery time is displayed at the top).

The delivery times can be either automatically generated deliveries based on the selected time interval or one-time deliveries.

The time remaining until the planned delivery is highlighted in color. The color scheme is defined as follows:

| Status | Description |

|---|---|

| -15 | Delivery date scheduled, manually or via interval. |

| +8 | The demand has been picked up at the point of origin and is on the train (delivery is expected soon). |

| +35 | The delivery was carried out successfully. The position is completed. |

The following functions are available for the individual supplier entries:

| Status | Description |

|---|---|

| Setting-up | Delivery date scheduled, manually or via interval. |

| Loaded | The demand has been picked up at the point of origin and is on the train (delivery is expected soon). |

| Delivered | The delivery was carried out successfully. The position is completed. |

| Skipped | The delivery could not be carried out. The quantity needed is still open. |

When loading, the quantity to be loaded is pre-filled with the values from the master data, but this can be corrected upwards or downwards.

In case of underdelivery, the missing quantity is automatically added to the next delivery.

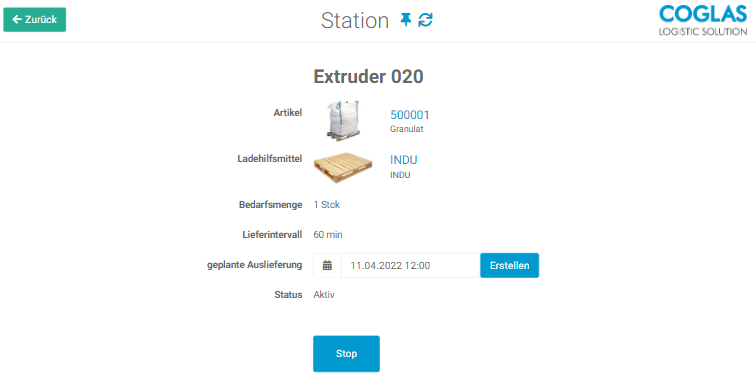

You can enter the station menu by clicking the Station button. In this menu you can stop the station, start it and create an additional delivery date.

When a station is stopped, you can either scan or select manually to change the product. This function can also be customized via the user roles.

The barcode used for the scan is the EAN13 barcode from the article master data.