Master data

Article master data can be entered manually or can be imported, see chapter Interfaces › Import / Export. In addition to the clear assignment of the article to the client, it is possible to store an article photo, which is displayed in the booking processes for illustration purposes.

The article images are saved in the jpg format and compressed to a width of 1000px if they are larger.

In addition to the basic data of the articles, such as article descriptions and the morphological data (length x width x height), process-relevant aspects can also be maintained:

| Name | Explanation |

|---|---|

| Number | Unique article number. |

| Name | Article number name. |

| Description | Text field for entering additional information. |

| Short description | Text field for entering additional information. |

| Client | Selection from a catalog as a value list = business partner to “partner type=client”. |

| GTIN | Global Transaction Identification Number, it is a unique 14-digit number used worldwide to identify trade articles, products or services. |

| Product category | Text field for entering the product category. |

Morphological data like length x width x height are to be filled in only for articles that are stored in pieces. For articles that are stored in meters, grams, cubic centimeters, liters, etc., all three dimensions must be left blank (ZERO). As a result, the largest LHM is always used for commi and packing planning.

| Morphological data | Basic mathematical units |

|---|---|

| Width | In meters |

| Depth | In meters |

| Height | In meters |

| Weight | In KG |

| Volume | “In liters” can be calculated automatically with this button if the width, depth, height are maintained. |

| Space diagonal | “In meters” can be calculated automatically if depth and width are maintained. |

| Nesting factor | To calculate the volume during picking or to determine the appropriate packaging size, these are hollow bodies that can be “stacked” to save space.

When picking an article with quantity > 1, the volume is not simply multiplied by the number of individual parts, therefore, but the factor is taken into account. |

| Setting | Description |

|---|---|

| ABC classification | Selection from a catalog with values A-F to divide articles into the respective categories. |

| Crash class | Selection from a catalog with values “empty”, 0, 1 to 11. The value 1 stands for heavy, 11 for light. The values “Empty” and 0 are evaluated last, i.e. after light. |

| Billing group | Selection from a catalog, see also billing of warehouse services. |

| Bulk material | A Yes/No value to specify whether the material is bulk or not. |

| Bulk density | In kg/m3. |

| Hazardous material | A Yes/No value to activate in the “Hazardous material” article tab. |

The selected article can be posted by default with a specific strategy in the goods receipt, returns, production or goods out process. The value can be changed individually at the respective process position in order to be booked with a different strategy.

| Standard strategy | Description |

|---|---|

| Standard-WE-strategie | Selection of a WE strategy. |

| Standard return strategy | Selection of a return strategy. |

| Standard production strategy | Selection of a production strategy. |

| Standard WA strategy | Selecting a WA strategy. |

| Shelf life | Description |

|---|---|

| Shelf life | Indicates the shelf life of an article in days. |

| Total shelf life warning | Issues a warning should an article approach shelf life at xx days. |

| Max. To storage after MHD | Defines the maximum time period between the youngest and the oldest MHD when storing together within a node (e.g. block) (remaining MHD period with the possibility of storage at the storage location). The configuration for merging can be done within the target setting of the strategies under “Feature Purity”. |

For the following attributes:

| Best before date required. |

|---|

| Batch required. |

| Special stock number (SSN) required. |

| Special stock number (SSN) 2 required. |

the following 3 inputs can be selected: Yes / No / Not set; these have the following meaning:

| Yes | If “Yes” is selected as the value, the selected attribute must be entered for the corresponding article. |

|---|---|

| No | If “No” is selected, no entry must have been made in the named attribute. |

| Not set | With the value “not set”, batch, SBK, SBK2 can be assigned with a value. |

| Disallowed inventory corrections | Determines whether and which inventory corrections may be performed. Selection values are increase and decrease of the article stock. |

| eKanban | Yes/No Selection. If selected = YES, customer order positions for the respective article will not be taken into account for inventory reservation. The positions are in the status “eKanban” and are ignored in the status calculation of the list header. These are accounting items that should only be handled by manual inventory allocation via picking and/or full pallet staging. |

| Customs articles | The customs article entered will also be assigned at the customer order start, replenishment minimum stock and order related replenishment if there is no free stock for the actual article. |

| Deactivated | Articles, once created, cannot be deleted again. Deactivated articles are not displayed in the selection for business processes. |

The following functions are offered for each article called up:

Here you can find the previously listed attributes for the selected article.

With the attributes can be changed. The changes are applied with Save.

With an article is duplicated with all its attributes, only a new number and a new client must be selected:

The changes are applied with save .

An article label can be printed here .

The “Packaging units” menu in the article master is used for container and capacity planning. One entry can be made for each loading equipment.

Applied are the packaging units goods receipt and there for the “Automatic collection”. The capacity calculation determines suitable containers from the packaging units of the article from the largest to the smallest. (See Goods receipt: “Automatic collection” the EURO pallet is used as default if there is no packaging unit).

For the packaging unit, the loading equipment can be entered and maintained with additional properties. If not described above, the default values are overwritten.

The button opens the editing mode for packaging units. A new entry can be created via the

button.

The meaning of each entry is:

| Entries | Meaning |

|---|---|

| The image of the loading equipment.

(The image from the loading equipment menu is not displayed). |

|

| Selection of the LHM. | |

| Quantity | Maximum uptake of the LHM. |

| Switch with values On/Off.

It is used the loading equipment for the customer order packaging planning. The loading equipment must have the property “Suitable for packaging=active”. Only activated “Article master packaging units-whole storage unit” are taken into account for packaging planning. These loading aids are charged first for packing planning from the largest to the smallest entry. The remaining quantity is calculated according to the normal packing schedule. |

|

| Barcode | GTIN of the article to the packaging unit.

Each packaging unit has a unique barcode! |

| Stacking factor | When storing in block storage, the stacking factor of the article is taken into account and the capacity of the block storage is adjusted. |

| Width | In meters |

| Depth | In meters |

| Height | In meters |

| Article | An article describing the loading equipment can be selected. An article master entry is required for this. |

| ABC classification | See the description above. |

The dialog can be used to save or discard the changes.

If alternatives to the article are offered, they are listed here.

In the demand request, the requested article is first checked to the available quantity. In case of shortage, the list of “alternative articles” is checked according to top-to-bottom order and, if it is available, the stock is reserved there.

With you can already assigned alternative articles:

- remove again (by pressing

),

- change the already assigned article (by searching

of a new article),

- or add another item

.

The originating article cannot itself be an alternative article.

Alternative articles are selected according to their order (priority).

The priorities can be changed for more than one article by selecting the priorities or by “moving up-down” the individual positions.

Using bills of material, the individual components can be assigned to an article that is to be manufactured in production (in the course of production, the required raw materials in the specified quantity are brought to the production line by means of transports and booked out. In exchange, the goods to be produced are booked in the specified quantity).

In the created parts lists can be searched and filtered, displayed results can be sorted.

The button can be used to add a parts list to the selected article. For this purpose, the quantity for the selected unit of measure is recorded and the priority for the transfer orders to be generated is selected. Bill of material can also be deactivated. The whole bill of material for an article can also be deleted (bill of material header there

).

After that, the articles necessary for production can be added . The necessary material/article and the required quantity are entered here.

The dialog can be used to add the position or cancel the acquisition without saving. There is no limit to the number of positions.

Positions that already been entered are displayed.

And can be edited via the button or deleted via

.

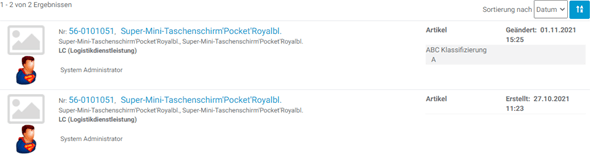

Inventory movements for the article can be viewed here, these can be narrowed down by search and adjustable filters.

As described in the bearing overview , the respective bearing units for the article are listed here.

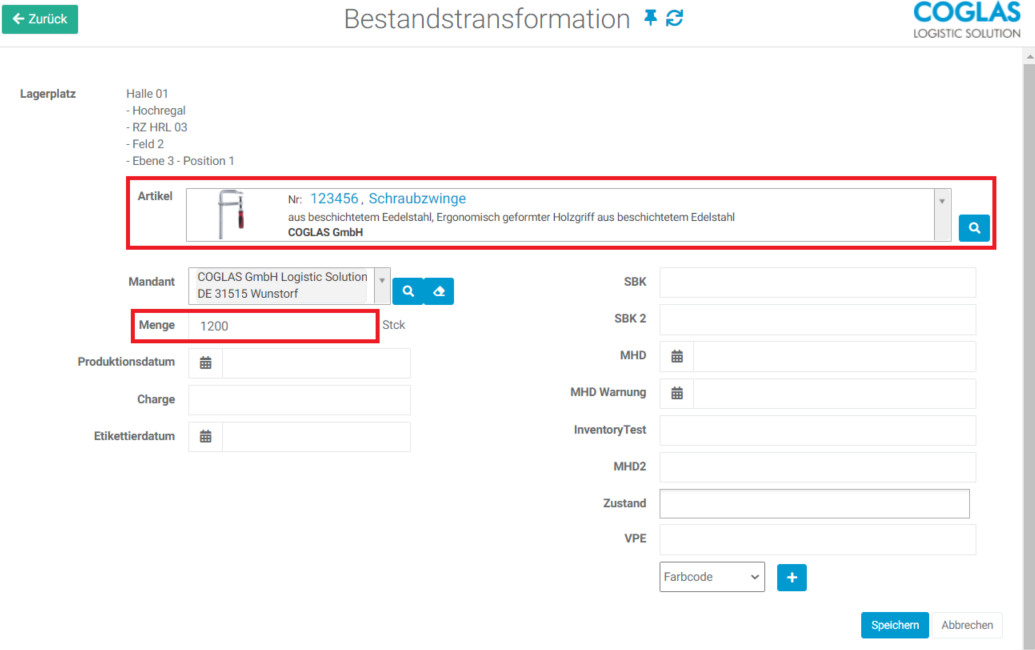

With the inventory transformation the user has the possibility to change all fields of the inventory details. The existing NVE/SSCC does not need to be changed in the process. Data such as article and quantity can be adjusted. The storage location cannot be changed. The inventory transformation differs in the option to customize the article and the quantity.

Functionality

| Button | Description |

|---|---|

| In the stock overview you can select a SU and change the attributes in the stock details. | |

| Now there is a possibility to transform the article. | |

| In the “Stock transformation” menu, another article can now be selected and the quantity adjust. | |

| With “Save” the new data record is saved on the existing SU. |

Establishment

It is not necessary to set up the function. However, there is a possibility to define the stock transformation type list.

The user can select 3 lists among the stock options:

| Selection | Description |

|---|---|

| Alternative articles | The stock transformation function reduces the selection of article numbers based on the alternative articles stored on the source article. |

| Product category | The inventory transformation function reduces the selection of article numbers that have the same article product category stored on the source article. |

| Parts lists | The function for stock transformation reduces the selection of article numbers on the basis of the parts list items stored on the source article. |

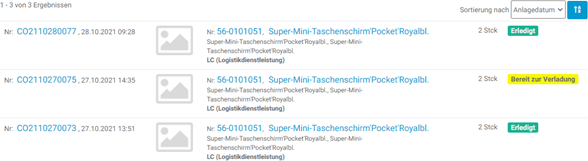

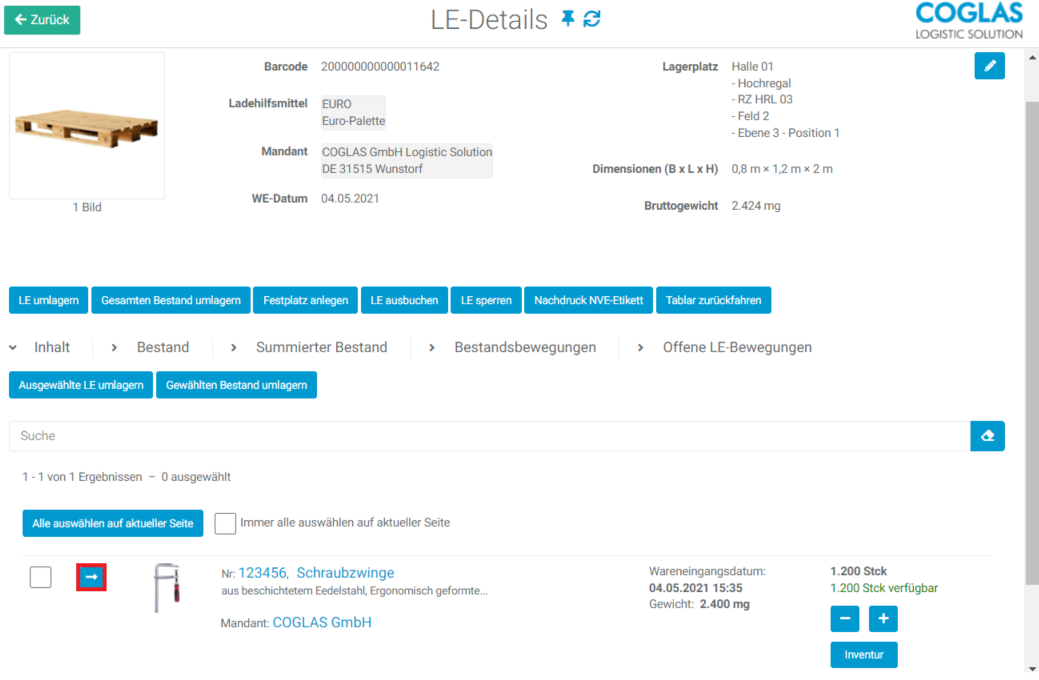

Via the warehouse overview, the user can see all storage units in the warehouse. A storage unit can be selected via the hyperlink:

This guides the user into the SU details:

There sounds the button to get into the inventory details:

After that, the stock transformation can be performed. The article and the quantity can be adjusted.

This completes the stock transformation and the SU has the same NVE but a different article:

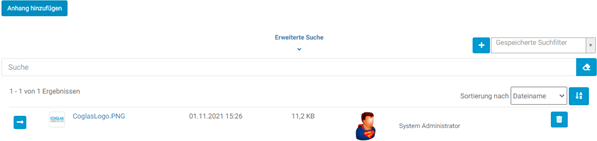

File attachments associated with the article are listed here (these can be images or files like .PDF).

| Reference | Description |

|---|---|

|

Not all mandatory fields have been entered, see also red marked fields. |