Goods receipt

In the production order, the finished goods / sets to be produced are listed with article and quantity. It is the notification of the production receipt. Production orders can be created manually or transferred via the interface.

The overview shows all production orders, these can be narrowed down with different filters and search requests. Search filters can be saved individually:

Via Add production order a manual production order can be created, from the list of displayed orders all orders that are not in the status Done can be changed additionally.

Provided

| Button | Description |

|---|---|

| Add production order | Adds a production order manually. The production order header contains, among other things, information on the planned production date, the supply strategy (supply of raw materials to production), the selected production line, and the strategy for disposing the finished goods in the course of the subsequent production input.

Number, client, production date, supply strategy, production line, remarks, reference no., reference no. 2, priority. |

| Allows you to change the production order header. | |

| Duplicates the selected production order together with the stored positions. | |

| Add new position | The position lists the stock qualifications of the goods to be produced. In addition to the article number, the quantity, and the optional characteristics such as batch or raw material batch, the loading equipment and the quantity per PRT on which the finished product is to be stored are also managed.

Article, Quantity, Batch, SBK….. The position can now be added or the process can be canceled via the “Production order…” buttons. |

| Select all on current pageUnselect all on current page | Selects all of the production order cancels them again. |

| Checkbox for selecting / deselecting production positions. | |

| Allows you to change a production position. | |

| Delete selected | Deletes the selected and selected production positions. |

| Selected duplicate | Duplicates the chosen and selected production positions as long as they do not have the status Done. |

| Start supply | This starts the production supply for articles where a bill of material is available. For the supply, the required articles are fetched in advance according to the supply strategy. Transfer orders can be found either under Picking or Transfer. The status changes to Waiting for transfer. |

| Add production input | Transfers the articles and quantities of the production order positions to the production receipt for later transfer of the finished goods to the warehouse. |

| Show production receipt | Shows the production input for the associated production order. |

| Set order done | Stops processing the production order and prevents further actions related to the list. The process is irreversible and does not allow any further bookings. The list status is set to Done accordingly.

The transfer orders already started for the production order remain in place, these must be cancelled manually via the respective control station! |

The “Positions” tab displays the production positions.

“Attachments” shows the files stored for the production order.

Under “Linked lists” all production orders and receipts resulting from this order are displayed.

The change history shows all changes to this delivery note.

The required supply strategies must be captured under System Strategies. See under Strategies.

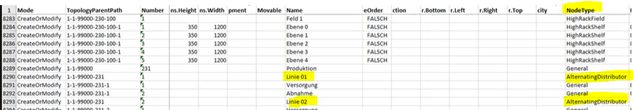

The production lines must be created in the topology. It is important to set the nodetype for these lines to AlternatingDistributor in the exported topology list and then imported it. A change to this nodetype is not possible at the frontend.

The following warnings may appear within the processes:

| Warnings | Description |

|---|---|

| No service has been stored under System Service Configuration for transferring data via the JSON interface. | |

| A production order was to be started without a bill of material being stored or an position being assigned to the order. | |

| One or more input fields were not filled with correct values or no values at all. These are now marked in red. | |

| Production order must be started and “Auto. start production receipt at complete provision of raw materials” should not be activated in the warehouse options. | |

| A production order should be started without an position being assigned to the order. | |

| A selected production order item cannot be deleted because it already has the status Done. | |

| The production input was started for consumables. |