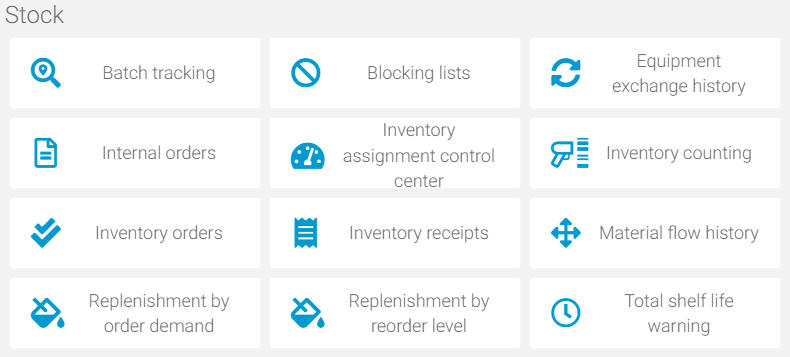

Stock

In the system menu, under the Inventory category, you can find the following processes for performing an inventory.

The inventory order defines, via various filter options, which goods or storage locations are to be inventoried by which client.

If an inventory order is started, inventory lists are created and the affected stocks/quants are blocked for further processing. These lists provide you with an overview of the processing status of the counts.

Inventory counting is used to record the stock in the warehouse.

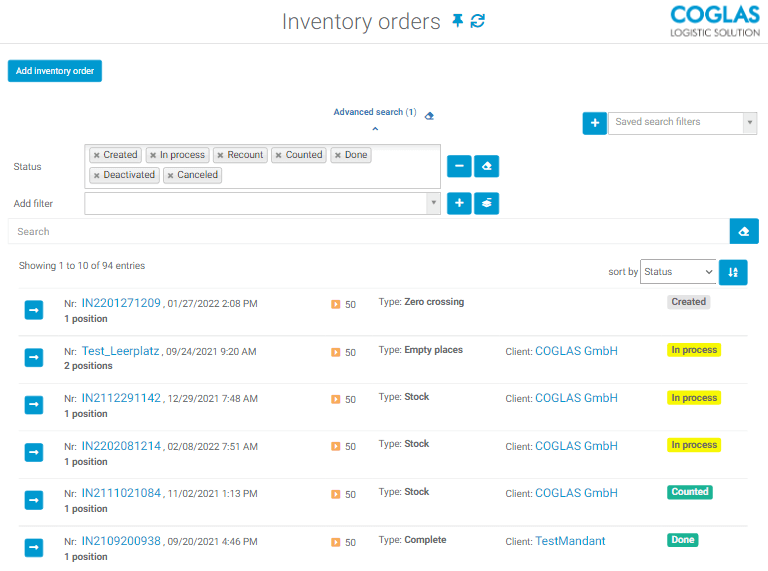

The inventory orders are displayed in an overview. An inventory order can have the following status:

| Fields | Description |

|---|---|

| Created | The inventory order was only created, but not started. |

| In Progress |

|

| Recounted | All initiated recounts were carried out. |

| Counted | All positions of the inventory order were counted. |

| Completed | The order has been fully counted and inventory has been completed, the new inventory has been updated to the LP/Quants, the LO lock on this order has been removed. |

| Deactivated | The created job has been deactivated and is no longer available. |

| Canceled | The created order was canceled. |

The display can be reduced via the filter status, via the search it is possible to display the desired search results.

The display can be sorted by status, creation date, inventory order number or priority.

![]()

Via button or the link to the inventory order list an inventory order can be called.

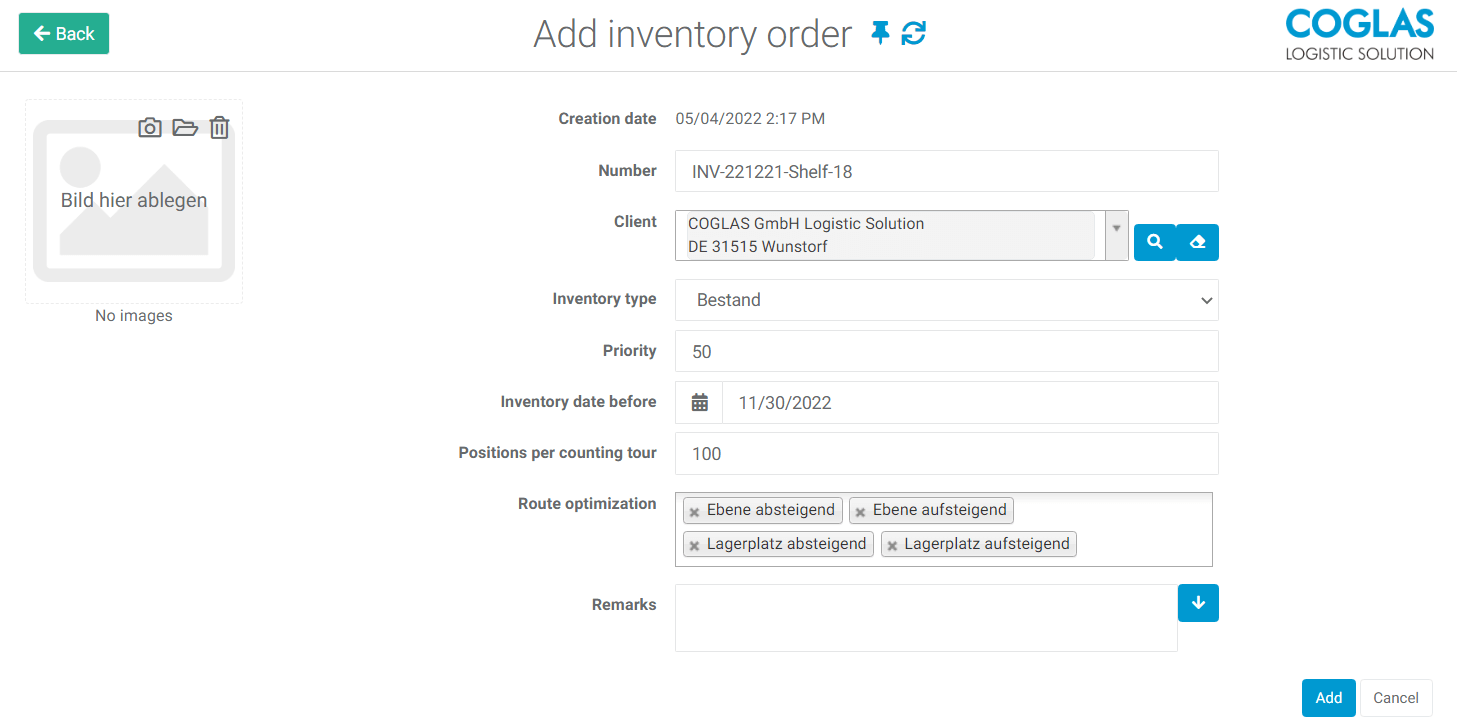

Via Add inventory a new inventory order can be added. The following fields must be filled in:

| Fields | Description |

|---|---|

| Creation Date | The creation date is set automatically and cannot be changed. |

| Number | A unique inventory number must be entered here (alphanumeric), this can be generated by entering ## and Return. |

| Client | Auswahl des Mandanten, für den die Inventurzählung gilt. |

| Inventory type | There are three types:

|

| Priority | Display of the priority of an order (1-100). |

| Inventory date older than | Takes into account only objects that have an older inventory date. |

| Positions per counting round | Number of pick positions that an employee is assigned one after the other to ensure spatial separation of the workers at the positions. |

| Running routine | Here you can select by storage location up and down, level up and down. |

| Remarks | Free/flowing text for remarks. |

|

Pressing the “Add” button adds the inventory order and the status changes to Created, pressing Cancel discards the entry. |

See also Preparing an inventory.

After the inventory order header is created, the following activities can be performed:

| Button | Description |

|---|---|

| The order header can be edited. | |

| The inventory order can be duplicated. ATTENTION: All positions will also be duplicated! | |

|

Here the counting positions belonging to the order are added, this is only possible as long as the order is in the Created status.

The storage location to be counted can be selected via the dropdown menu. The top level (i.e. the node currently displayed) + all LPs “below” the node are always used to select the inventory locations. If, for example, the main node STORAGE is selected, this inventory order runs over the complete topology, see also Preparing an inventory. Optionally, a specific, single item can be selected over which the inventory should run. |

|

Via Start inventory, inventory count documents and transfer orders for counting are created according to the specifications in the positions. The affected stocks are blocked, this is also displayed in the stock overview (gray fields) as well as in the overview of SU’s.

Please note that the start of the inventory will take some time in case of large counting quantities. |

|

Order positions can be selected and deselected here. |

| Manual selection and deselection of a single position. | |

|

If positions have been selected, they can be deleted as long as they are in the Created status. |

| A single position can be deleted via the “trash can” as long as it is in the Created status. | |

| Edits the single position. | |

|

Cancels the complete inventory order, already counted positions are discarded, blocks are removed. |

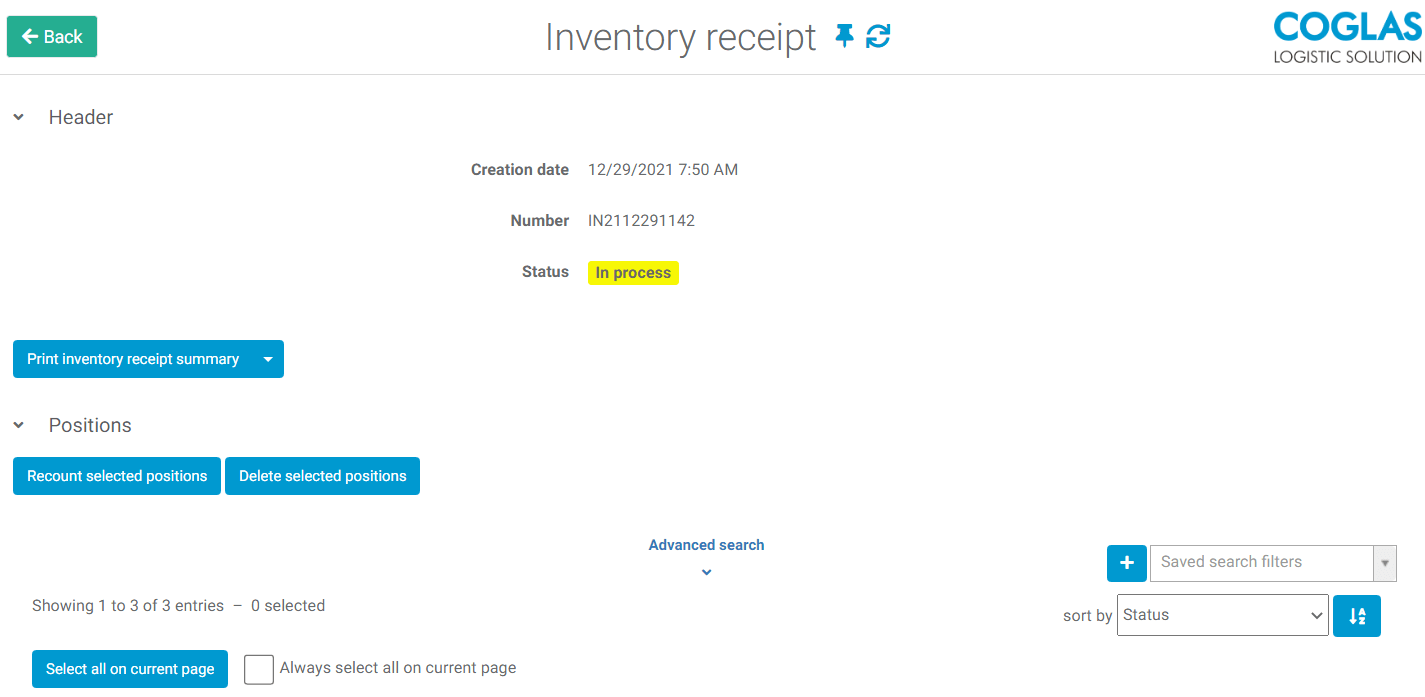

The inventory lists provide an overview of the started inventory orders in general as well as further information within the lists. You can view the progress of the inventory as well as the deviations from the expected result and initiate recounts if necessary.

The display can be reduced via the filter status, via the search it is possible to display only the desired search results.

The display can be sorted by status, creation date or number.

![]()

Selecting opens the corresponding inventory list for a detailed view.

| Button | Description |

|---|---|

| Prints the inventory documents of the positions belonging to the inventory list.

|

|

|

List positions can be selected and deselected here. |

| Manual selection and deselection of a single position. | |

| Initiates another count of an already counted position, this position must be selected. |

The detailed view of the individual position shows the following if the count has already been performed once:

- The target value (goal).

- The actual value (actual count).

- Difference absolute.

- Difference in %.

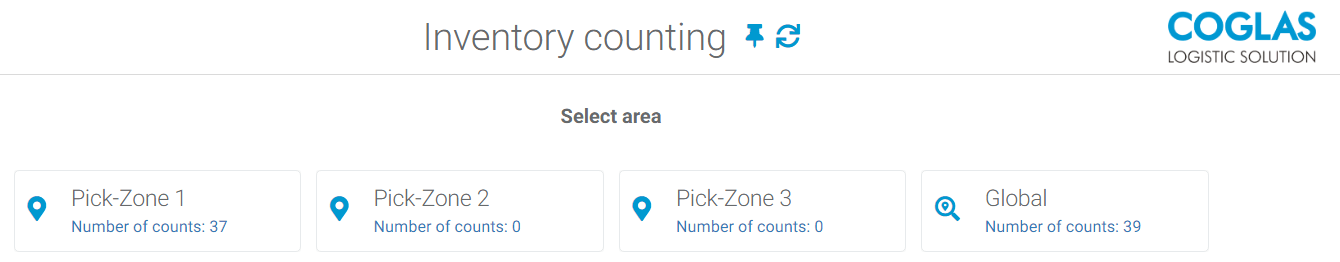

Under Inventory counts the started inventory orders are listed. The counting team then selects a list from the (assigned) area and starts the inventory count:

Please note that here the positions of the not yet by the positions deposited in the order per counting round are indicated. Example:

If an operator starts the list DLK R5, which was stored with positions per counting round = 100, this list is removed from the view.

For the DLK R6 list, the display changes to 177 items because 100 positions have been assigned to the MA for the counting round.

Depending on the storage type and assigned count type (stock, empty storage), different masks are displayed.

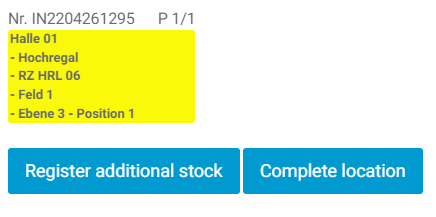

Generally, you are instructed to drive to a destination storage location and validate it by scanning for count acceptance:

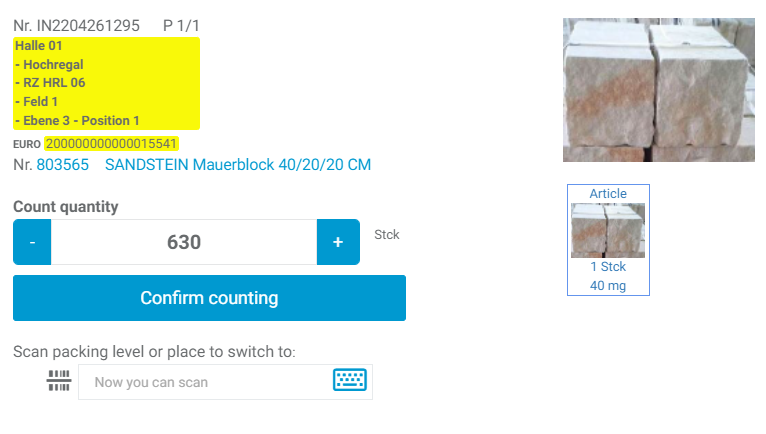

After that, there can be two possibilities: The place has accounting in the Coglas stock and the inventory must be made and recorded:

After the count is completed, the storage location must be closed or additional stock can be entered (see Entering additional stock).

Or the space is “empty” for accounting purposes and must be receipted:

For the different storage types, e.g. continuous channel, tray or similar, a validation of the respective carrier units is necessary to start the counting.

(In this example, counting is done at a channel in the throughput channel where SLC (small load carriers) are located.

To count the individual SLCs, the storage unit number assigned to the SLC must now be scanned,

so that inventory collection for SU carriers can begin).

For block storage, the barcode of the block storage to be counted must be scanned.

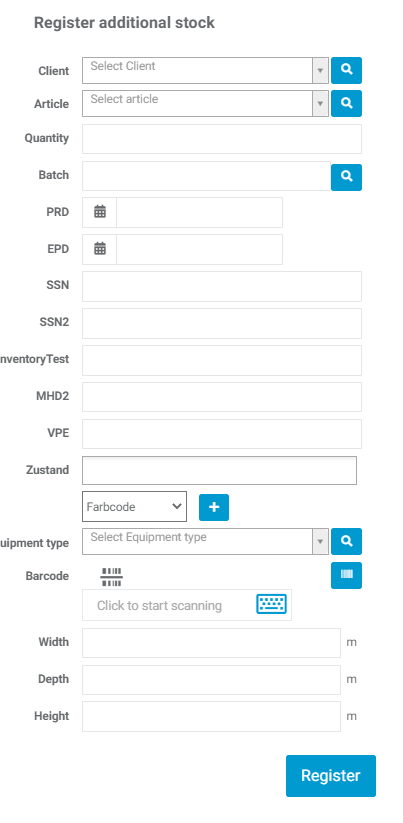

If additional inventory is “found” during inventory entry, it can be entered and posted directly.

This should only be performed by experienced Coglas users, as a new loading unit incl. the information necessary for this storage quantum must be recorded (see picture).

Order volume

It is necessary to ensure that all transports to the warehouse, internal transports and picking have been completed (for this client) at the start time of the inventory.

As a result of the stock counts, reserved stocks may then no longer be served (shortage), which can lead to cancellations during picking (no more stock in the picking zone, no more replenishment stock available, or similar).

The order volume for picking must be clearly defined and estimated. In accordance with the motto “Better start orders further”, “less is better” here shortly before the start of inventory

Delimitation clarification

It must be clarified with the customer whether there are time points for booking deadlines for incoming and outgoing goods (also for booking in external systems or confirmation to ERPs).

At the time mentioned, it should then be clearly delineated which goods must be counted or not.

Goods receipts

Goods receipts that have already been posted but have not yet been transferred to the warehouse are to be included or not in accordance with the accrual declarations. If entry is desired, ideally these should be transported directly to the warehouse BEFORE inventory order creation, or posted to a block location, and then that block location added to the inventory count.

Goods receipts that are not to be counted for inventory should ideally also be recognizable as such by “visual blocking”. It is not recommended to move these goods to the warehouse during the inventory, as they might then be recorded as additional stock.

Customer orders / provisioning / picking

If there are transport orders from storage locations to be inventoried, the following may happen:

- The transfer order can be processed

- The inventory count will approach this storage location as a target result and perform a count there; depending on the transports/picking that have taken place, this may mean that no more stock is found there.

- This can lead to evaluation problems after the inventory has been completed (stock before inventory, stock after inventory has been completed)

It is recommended to process and complete all open sales orders or cancel the transfer orders BEFORE starting the inventory.

Otherwise, when completing the inventory, in case of any stock adjustments that result in reservations no longer having enough stock, the transfer of the new stocks for these articles/counts cannot take place. In this case, the transfer order for the article must be canceled anyway in order to allow the inventory to be closed.

Mixing pallets

Mixed pallets in stock, where the quants are only on one SU, should be dissolved.

Mixed pallets, where there are articles in different quants on one SU, must be broken up, as a correct assignment of the counted stock to the article is not given.

If the quants are on SUs that are on a carrier pallet, in the inventory count entry process you will have the slowdowner in identifying the individual goods on the carrier SU, again the fewer the better, the faster.

Stock list before inventory

It is recommended to export an inventory list before starting the inventory.

Create inventory orders

One creates an overview of which goods need to be counted at which storage locations. In addition, one determines the number of SUs/ LOs that must be counted.

By specifying the duration of an inventory, it is now possible to determine a daily/hourly rate that defines the number of counting teams (Please note that sufficient terminal equipment is then also available/lifting cages or driving cages together with floor conveyors, battery/battery runtimes must be taken into account).

About the known topology of the storage system, it is NOT recommended to work with only one inventory order, which then determines all storage locations “downwards” from the main node.

BESSER ist es die Inventuraufträge an die Topologie des Lagersystems zu koppeln, also zum Beispiel einen Inventurauftrag für Regal 01, 02, Block-Kühllager33 etc. zu erstellen.

This increases the number of inventory orders, but it is possible to have a much better allocation to counting teams, and at the same time a better progress indicator of the inventory taking via the status of the respective lists.

Reference

As a rule, calling up the inventory orders via STOCK COUNT is always significantly faster than a COMPLETE COUNT. After the inventory has been counted, an empty space check can be performed if desired.

With COMPLETE COUNTING, the recording of all stocks of all MANDATES in the selected storage area to be counted is also ALWAYS carried out, as otherwise no assignment and checking of the empty spaces is possible.

Inventory list after inventory closing

When the stock list is exported after posting the inventory, the lost stock is of course also specified as stock.

This means that it is mandatory to delete all stocks from Lost that were NOT found (Alternatively, you can also post these stocks to a block “PermantentLost”, for example, in order to have the losses documented in the system. However, this block must not be located in the BillingZones or AvailableStockZones).

All inventories found should be posted to the Found storage location and from there to the “correct” storage location after the inventory is complete.

The bearing options can be used to control:

- Activate zero crossing inventory.

- Activate annual inventory.

- Inventory on key date: Storage location must be confirmed.

The following warnings may appear within the processes:

| Reference | Description |

|---|---|

|

An inventory order was started although there are no inventory order positions. |

| Positions can be deleted only if they are created in the status. | |

| Only counted positions can be recounted. | |

|

When duplicating inventory orders, no or no unique number was recorded. |

–––

Last update: 22.12.2021, v2.0 by Buttler