Goods receipt

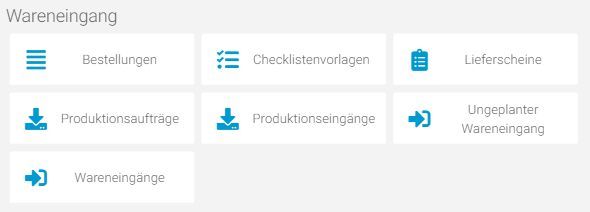

The goods in describes the process to the receipt. Access is to a purchase order or delivery bill or is expected from production. This is done after a planned notification as well as for the unplanned one. Other functions for goods receipt include data entry, receiving inspection, receiving and storage.

Goods receipt uses sequential processes. Each process step has its own overview with all the functions required for it.

| Overview processes | Description |

|---|---|

| Order + delivery note + goods in |

Entry of the order and processing to the delivery bill and goods receipt. |

| Delivery note + goods in |

Entry of the delivery bill and processing for goods in. |

| Production order + Consumption + production receipt |

Capture of the production order and processing to consumption and production receipt. |

| Unplanned goods in | Posting of the unplanned goods in. |

- Advised additions (planned WE). These receipts are announced by purchase orders and delivery bills (notifications) and counter-posted via the actual quantities for reconciliation.

- Other additions (unplanned WE). These additions are not notified

The advices can either be transferred from the host or entered manually by the user. The advice data refers to articles and quantities that will be delivered and stored in the future. A variety of stock qualifications can be recorded in the process.

- (Optional) Purchase order: transmission of an order to suppliers for ordering goods.

- Delivery bill: Notification of a planned delivery of goods

- Goods receipt: Matching and posting of the actually delivered goods in relation to the previous delivery bill.

- Receipt: transfer of the goods to the warehouse. Planned by means of system support via transfer orders to the target storage location, or unplanned via selection of the putaway location by the user.

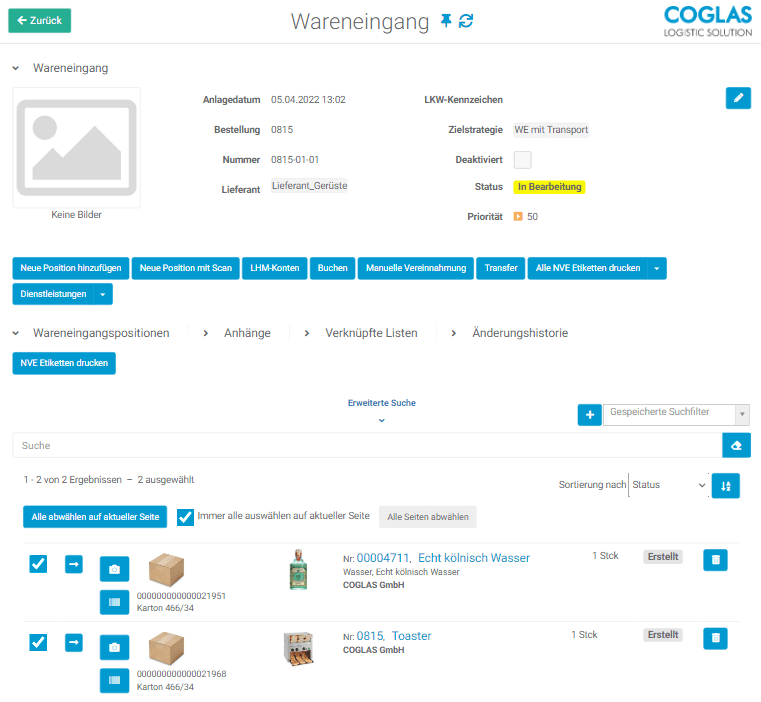

As soon as the notified delivery has arrived, a goods receipt is generated on the basis of the delivery bill. In principle, it is possible that the incoming delivery deviates from the notification in terms of article scope and/or quantity. Over- and underdeliveries are therefore possible. Deviations from the advice note can be corrected by adding, deleting or editing the goods receipt positions.

Optionally, any number of goods receipt lists can be entered for a delivery bill, relationship 1:n. All positions of the delivery bill are always transferred to the goods receipt. For example, if the delivery bill is received in parallel at different goods receipt locations, the positions/quantities that are irrelevant for the employee can be removed from the goods receipt bill. After the goods receipt has been completed, the quantities received flow back into the delivery bill and are compared there with the target quantity.

| Button | Description |

|---|---|

| Print NVE labels | This creates a PDF preview of the LE labels of all selected positions. These can either be stored on the device or output from any printer. |

| Services | Additional activities can be entered that are to be taken into account in the course of the billings. The desired services must first be entered in the course of the billing configuration before they can be used in the goods receipt. Further information is provided in the chapter Settlement › Warehouse services. |

| Billing | Opens the invoice for the current goods receipt and displays all relevant positions. Further information is provided in the Settlement chapter. |

| Open checklist | If the checklist option is activated, all check criteria must be validated manually before you can start posting the goods receipt. Every change to the checklist is logged in the change history. The configuration of the checklist can be done client specific under Goods Receipt › Checklist Template. |

| Booking | When posting, transfer orders are generated for moving the storage units based on the stored strategy. The status of the positions is changed from “At the gate” to “Waiting for transport”. In case of an unplanned putaway, the storage units remain in the goods receipt after posting and have to be put away manually. |